- E-mobility and electrotechnical devices

- Coffee and other household machines

- Air heat exchangers and water treatment equipment

- On- & off-road motorcycles

- Medical and laboratory equipment

- Power tools for construction

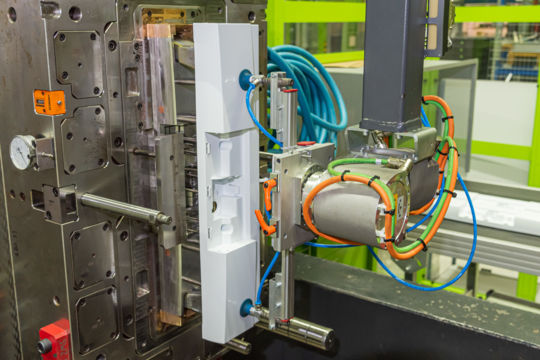

Anyone who uses the coffee machine, connects the electric car to a charging station, picks up a hammer drill, or rides a motorcycle through the countryside encounters PLASTON at best. PLASTON produces high-quality plastic housing parts and technical components for

The surface of visible parts and decorative components can be labeled and printed. PLASTON offers various techniques for this finishing: